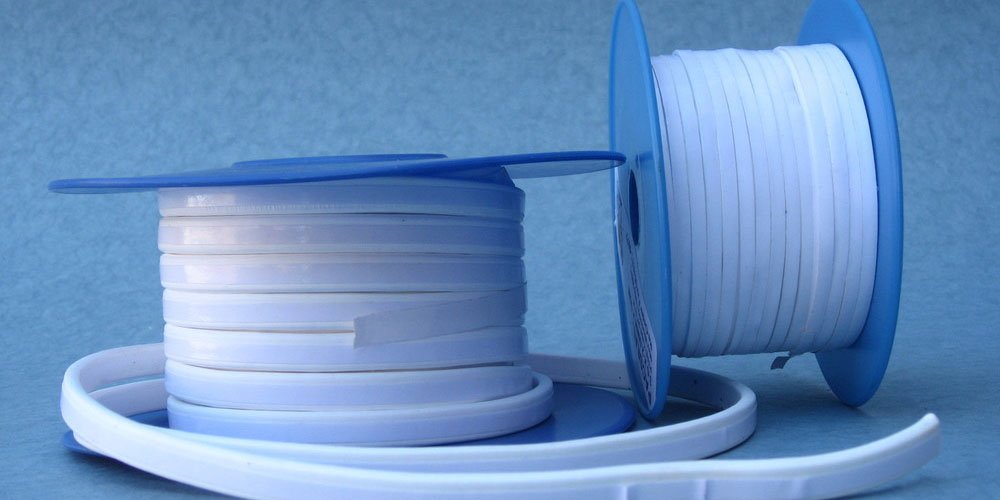

One of the issues with using valves in any machine or pipe is the worry of the liquid leaking out after the valve has been closed. In such situations, Teflex PTFE Valve Stem Packing comes in handy for you. It works to ensure that the liquid is tightly closed in, and there is no chance that it will leak out. If you have no idea how valve stem packingworks, here are the steps to installing and a couple of guidelines on how to replace the stem packing when it is damaged.

Replacing packing

After a while of using the valve packing, it grows old and damaged. One of the ways to spot damaged packing is by liquids leaking from the valve. If you realize there is a lot of liquid leaking that cannot be controlled even by a gland follower, it is time for you to replace your packing. Different packing is replaced in different procedures, but the key ones remain the same. Here are some of the steps you should follow when you are removing the packing.

Get the glands and follower nuts to loosen, then open the dog bolts. Remove the gland followers and the packing rings. The step is very easy because the pieces function like a corkscrew. In case there is a lantern ring, remove it next. Remove the packing rings left, then check the old packing to confirm if it is old and worn out. In situations where the packing was in good condition, there is a chance that there is a more serious reason aside from damaged packing. You might have to get a professional to look at the valves and shafts at this point.

How to install the new packing

Once you are done removing the old packing, it is time to install the new packing. Depending on the liquid passing through the valve and its corrosiveness, you might have to do this a couple of times to keep everything in good working condition.

Clean the exposed side of the shaft using nonflammable and nontoxic solvent ensure that it is clean and free of any debris. To get it clean, you must brush it down first before using a rag to clean it up. Measure the distance between the shaft and the stuffing box, then figure out how many rings will be required. Get a suitable mandrel that is the same size and the distance from the shaft, then wind your packing around it and cut the rings you need. Lubricate the rings and insert them into the packing ring as far as the cyan go. Once you are done, then you can close the valve.

Final thoughts

To ensure that the packing works, ensure you are accurate with your measurements. Missing out on your measurements will make the packing either too loose or too packed and bother of these leads to leaking. If there is still leaking after replacing our packing, it is recommended that you get a professional to help you figure out what the issue might be. It would be best if you replaced your packing every so often because it tends to wear out with time.