Understanding what Flexo Printing is

You may think that digital printing is just about mere gimmicks or elements that make a huge splash for some time and then fade. That thought may not be true entirely. Interactive print is a crucial element of today’s print shop. The demand for print technology is expected to rise.

What is Flexo Printing?

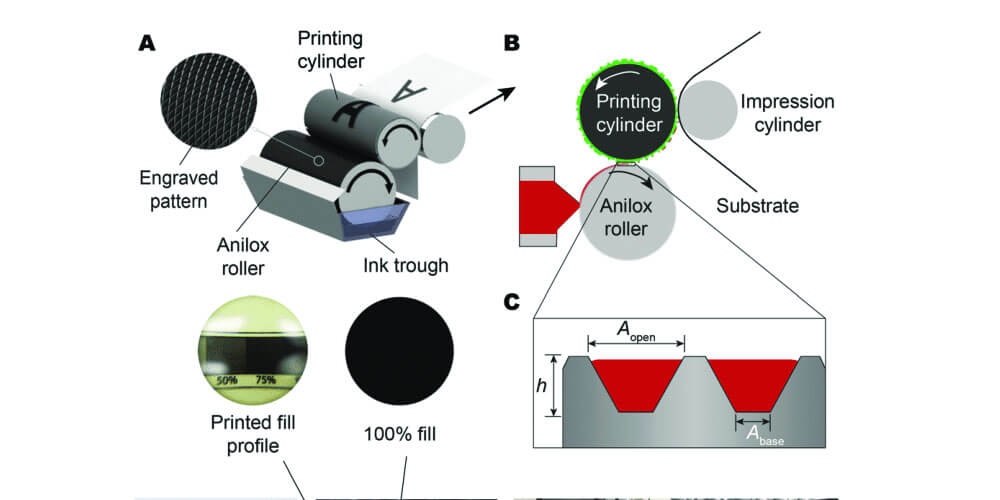

The typical Flexographic Engraving Equipment comes in four major types; the first one is a fountain roller, an anilox one, the impression cylinder, and the plate cylinder. The roller therein delivers some ink straight from a pan. The ink is then directed to ceramic steel that meters the anilox roller. After that, it is channeled to the plate of the cylinder.

The ink on the roller will then get placed on the substrate. The paper then passes in between the cylinder as well as the plate. A polished metal known as the impression cylinder is used to apply some pressure needed to transfer the ink from a plate into the substrate.

The Future of Flexo Printing

Active printing by flexo is crucial in today’s printing world. Flexo printing is a technique used for convex direct printing. It is mostly used for printing plastic. Today, it is a dynamically developing sector of the printing market. This is because of the possibility of the growing demand for plastic products and the continuous application of printing on absorbent bases.

Flexography refers to a unique web printing process. It is often utilized to print large volumes of papers and corrugated boards. It may also be useful in printing films and paperboard. Many products printed via flexo presses are such as gift wraps and tissues.

Basics of flexo printing and how it works

Flexo printing occurs when a photopolymer plate has been circled on a rotating cylinder. Different colors can be used. Just like the letterpress process of printing, the graphics will be raised from the plate’s surface. You should be left with raised parts of a plate. These surfaces are inked eventually.

Flexo is not what you want to term a new form of technology. However, it is still evolving with several innovations. The developments render it useful in that it is one of the most reliable methods for producing large orders coupled with top-notch custom labels and at rapid speed.

Over and above, flexo adapts easily to various materials. Some of these elements include the EF multi-substrate flexo printing. This one type of print can hold up. It can also easily be printed on various substrate types such as metal and paper.

The degree of value in printing using flexo is going to proliferate. This is based on the growing demand for printing by younger generations. Millennials are not the only people with a rise in demand for printing.

However, if the technology staples of the generation indicate the rise in expectations, you will realize that interactive print becomes a fundamental need in the communications department.

Final Thoughts

The expectations for a quick turnaround are still growing as the prepress software makers automate the prepress processes. In the future, automation will cut down the demand to outsource placemaking while minimizing the growing risks of mistakes when it comes to designing files for flexo prints. These prints should be converted into various package sizes.